Active thermography software IRBIS® 3 active

The material properties of products can be tested without contact by applying a heat impulse to the test object by means of infrared thermography. This process, which is also known as heat flow- or active thermography, allows a non-destructive detection of material defects, such as joint flaws, blowholes, cracks or delamination.

With the newly developed active thermography software IRBIS® 3 active, you have a modern and universally applicable tool for thermographic material testing at your disposal. Thermography sequences, which are synchronised with the excitation unit, are edited and displayed as a false colour result image by means of a specially developed analysis procedure. Thus, even small defects can be recognised repeatedly and reliably. The selection of the implemented evaluation algorithm largely depends on the material and geometry of the test object as well as on the type of defect to be detected.

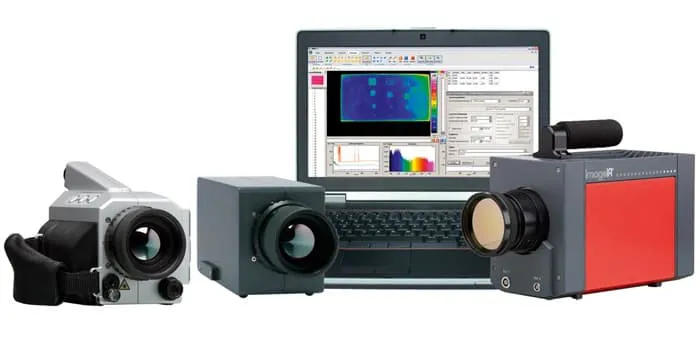

Besides InfraTec's high-end camera series ImageIR®, the utilisation of powerful micro bolometer cameras for active thermography is another completely unproblematic solution nowadays. The excellent thermal resolution of the latest VarioCAM® high resolution models of less than 0.03 K, as well as their fast image refresh rate and trigger-ability are a perfect basis for the solution of a variety of problems.