Play it Safe

Pyroelectric detectors are sensitive components. To ensure that they provide correct signals throughout their entire service life, a precisely defined atmosphere must prevail within their housing. Even tiny quantities of moisture inside the detectors, for example, produce leakage currents and thus cause deviations from the function parameters. Only a hermetically sealed housing fastening that is stable over a long period of time can prevent this. With financial support from the European Fund for Regional Development of the European Union, InfraTec has developed a broadband, solderable infrared window that provides such protection.

Until now, such windows have been adhesive bonded to the cap of the detector housing. However, this cannot ensure that the very dry nitrogen filled in the housing cannot mix with other gases from the environment. The result of water vapour diffusion, for example, would be increased detector noise.

Partners with expertise in the field of micromechanics

For this reason the new optical window is soldered. This joining technology withstands the loads of an extremely moist and warm climatic environment and thus creates the conditions for gas analysis with infrared detectors even under demanding measurement conditions. The window consisting of a silicon substrate also offers a tough anti-reflective coating (ARC). In conjunction with the large aperture opening, it is ideally suited for the new Pyromid® multi channel detectors of the LRM series from InfraTec.

Anti-reflective coating and large aperture opening – the major share of the development work involves these two features. Optical layers such as the ARC are normally applied by evaporation. In this case, however, chemical vapour deposition (CVD) was used. The Center for Microtechnologies (ZfM) of Technische Universität Chemnitz contributed the necessary expertise for this project. Its staff are experts in the field of silicon micromechanics, they are very familiar with the development and production of conductive and insulating layers and have mastered the production of layer systems for microelectronics and microsystems technology.

Thinking outside the box

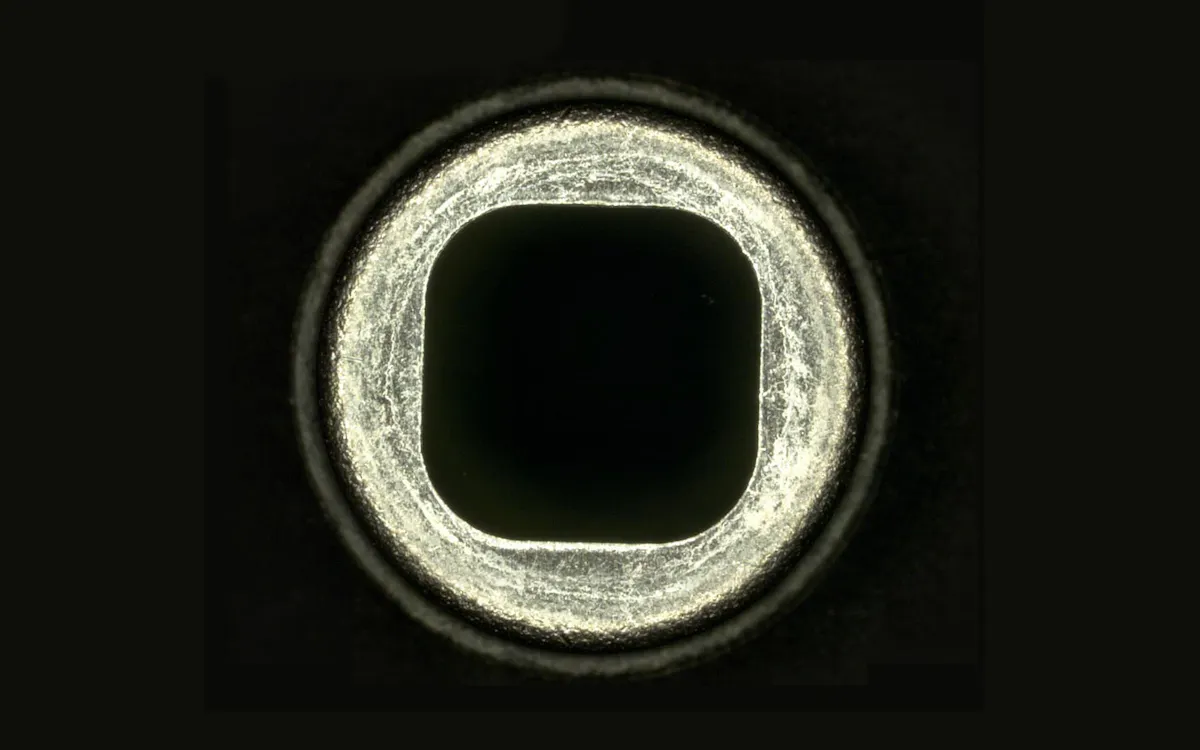

The ZfM also assisted in implementing an additional central idea of the developers from InfraTec. The channel filters within the detector are characteristic of the new Pyromid® multi channel detectors. To ensure that sufficient radiation strikes the narrowband filters through the central window located in the detector cap, it must be as large as possible. On the other hand, a sufficiently wide soldered edge is required to ensure a reliable connection. The solution for this apparent contradiction has exactly eight corners. Filters with an octagonal contour ensure, for example, that a filter size can be achieved even for the soldered entry window of (6.1 × 6.1) mm² for the TO-5 housing.

Detailed fine leak tests, fracture tests and temperature shock tests have demonstrated that this method has proven to be effective. The solderable infrared windows are now extending the product range of InfraTec and are paving the way for the use of the new Pyromid® multi channel detectors especially for gas analysis under harsh environmental conditions. Potential applications include the measurement of exhaust gas, medical applications as well as for use in devices that need to withstand cleaning cycles, such as steam sterilisation.

Get further information about pyroelectric detectors by InfraTec