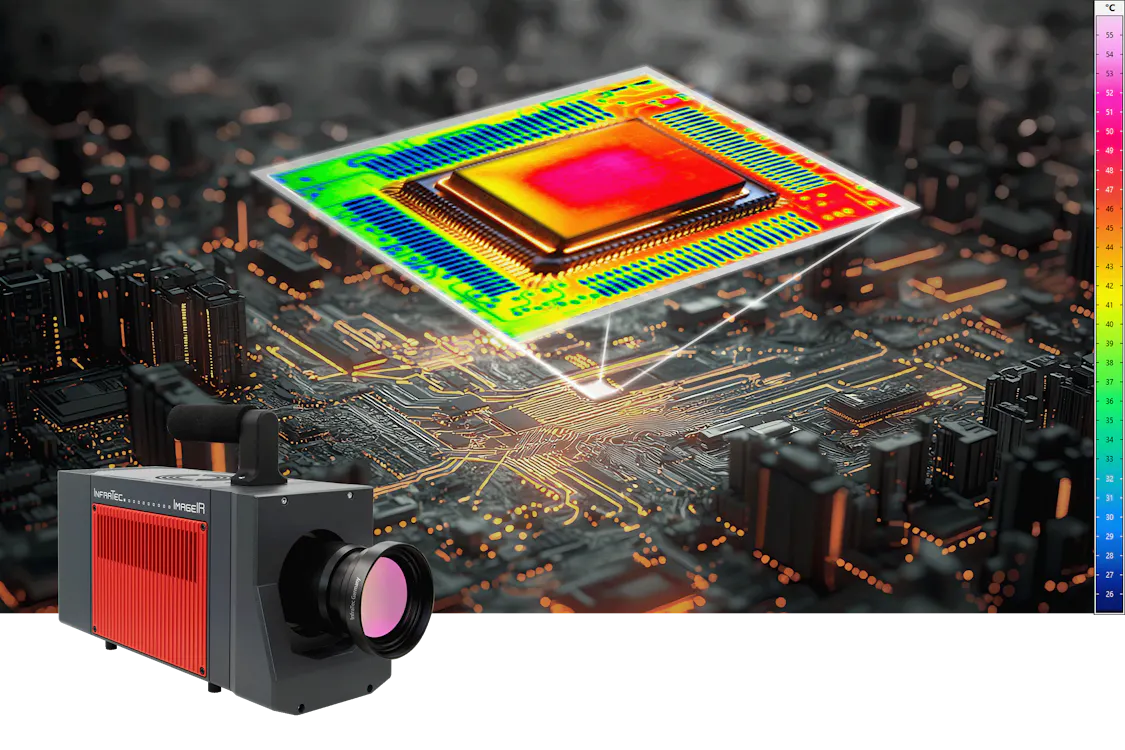

ImageIR® 12300: Next Level Details

The new ImageIR® 12300 from InfraTec is the radiometrically calibrated infrared camera with the world's highest commercially available native resolution of 5.2 megapixel. The powerful top model of the ImageIR® series allows very fine structures on large area measurement objects to be resolved with unrivalled detail.

Modern production technologies demand that ever larger area objects be examined in a consistent and greater level of detail. The new ImageIR® 12300 satisfies this requirement due to a cooled high performance photon detector with a native resolution of (2.560 × 2.048) IR pixels and combines maximum geometrical and thermal precision in one camera.

Standard cameras with (640 x 512) IR pixels need at least 16 consecutive measurements to achieve the same level of detail as the top model of the ImageIR® series from InfraTec. Thereby a separate analysis of all 16 images may be required or merging them into a thermal image. Instead the ImageIR® 12300 renders the measurement not only in unrivalled image quality but in just one exposure which guarantees the synchronism of all data collected.

The ImageIR® 12300 combines precision, speed and flexibility

The modular design of the new InfraTec infrared camera allows a customised configuration for the respective application. If requirements change, the camera can be retrofitted later, which further future-proofs the user's investment.

The interaction of highly precise interchangeable lenses from wide angle to microscopic with the freely configurable and motorised adjustable filter aperture wheel makes the ImageIR® 12300 the ideal tool for a wide range of measurement tasks in industry, research and development. Due to a frame rate of up to 140 Hz, both, dynamic processes and rapid temperature changes in a range of (-10 … 1,700) °C (optionally up to 3,000 °C) can be examined. In the high-speed mode (binning) thermographic images can be captured in full frame mode at up to 1,600 Hz.

Brilliant image quality with interchangeable infrared lenses

The high-performance photon detector of the ImageIR® 12300, which operates in the spectral range of (3.4 ... 4.85) µm, is comparatively small despite its high geometric resolution. This is possible thanks to a unique pixel pitch of just 5 µm. Measurements with the ImageIR® 12300 come with an outstanding thermal resolution of 0.022 K in the high-speed mode. As with all other high-end cameras of the ImageIR® series a wide range of high quality interchangeable infrared lenses can be used.

Integrated intelligence for more independence

The ImageIR® 12300 is equipped with high performance electronics with impressive processing bandwidth. IR image data obtained can be recorded internally, analysed using implemented algorithms and used to control the high-end infrared camera.

The ImageIR® 12300 is designed for standalone operations completely without a PC. Alternatively, data can be output in real-time via various interfaces to high resolution displays as well as for external processing or storage. The integrated web interface allows for operation and remote control of the ImageIR® 12300 by smartphone or tablet.

The camera has numerous interfaces for external sensors and triggers. The connectors are equipped with industrial grade plug connectors that maintain the degree of protection, ensuring safe operation even under harsh conditions. Like all cameras in the series, the internal trigger interface of the ImageIR® 12300 guarantees highest time precision and repeatable triggering and synchonisation.

Users also benefit from the infrared camera's 10 GigE interface which can transmit data up to 10 Gbit/s thus also high-resolution frames at the maximum frame rate of 140 Hz. Due to the use of state-of-the-art fibre optics, the connection is completely insensitive to electromagnetic disturbances, even at distances of up to ten kilometres.

The ImageIR® 12300, like all cameras in the ImageIR® series, is protected by an industrially suited, closed housing made of high-tensile aluminium alloys and suitable for use in rough environments (IP54). A carrying handle at the top of the device makes it easy to handle the robust infrared camera. The proven Stirling cooler ensures the long service life of the camera and a permanently high quality of the measurement results.

Best results with IRBIS® thermography software

All infrared cameras from InfraTec are delivered with the powerful control and analysis software IRBIS® which is developed by InfraTec inhouse. This software comes in various packages and is also available as part of the complete thermography solution. The software facilitates the intuitive and convenient camera operation. It also allows for efficient data acquisition internally to the camera or directly to the hard drive of a control computer. Moreover, it provides numerous analysis functions and tools for the clear depiction of the measuring data generated.

The modular concept of the IRBIS® thermography software allows for a customised software tailored to customer’s requirements and application focus and enables universal use in a vast range of areas.

ImageIR® 12300: High-end thermographic camera for multifaceted measurement tasks

Due to its extraordinarily high resolution, the ImageIR® 12300 can always bring its strengths to bear when large area measurement ranges need to be analysed in detail and at once. The use of the camera provides a significant increase in efficiency and provides maximum accuracy by preventing geometrically induced measurement errors.

In practice, this means, for example, that large areas can be captured with a single recording or image. In this way, flight time and thus costs are saved when being used airborne. When it comes to failure analysis in microelectronics, even complex electronic devices (circuit boards) can be analysed promptly and with maximum sharpness of detail.

Using full potential with customised complete packages

The ImageIR® series from InfraTec offers high-performance high-end cameras for industry, research and development. However, the full potential of the thermography systems only becomes apparent in individually customised assembled packages which are adapted to the respective measurement and testing requirements on site. Fast infrared precision lenses, an efficient control and analysis software and a highly precise, repeatable triggering open up a wide range of applications for users. This ranges from active thermography to micro-thermography and aerial thermography up to safety applications. The infrared cameras can also be integrated as components in turnkey automation solutions from InfraTec.