![INDU-SCAN base / Thermography Automation Solution INDU-SCAN base / Thermography Automation Solution]() 2024-11-07INDU-SCAN base – Thermography Automation Solution for Industrial ApplicationsReliable Thermography Monitoring System for use 24/7Read onDownload ZIP-File (10128 kB)

2024-11-07INDU-SCAN base – Thermography Automation Solution for Industrial ApplicationsReliable Thermography Monitoring System for use 24/7Read onDownload ZIP-File (10128 kB)InfraTec is expanding its portfolio with the addition of INDU-SCAN base, a flexible and cost-effective thermography solution for use in industrial applications 24/7. The system supports continuous thermographic measurement of temperatures and monitoring of production processes for early detection of faults and their causes.

![InfraTec Webinar: High-Resolution Aerial Thermography InfraTec Webinar: High-Resolution Aerial Thermography]() 2024-09-23Online Event: High-Resolution Aerial Thermography (November 2024)The Infrared Eye in the Sky – Aerial Thermography with InfraTecRead onDownload ZIP-File (3428 kB)

2024-09-23Online Event: High-Resolution Aerial Thermography (November 2024)The Infrared Eye in the Sky – Aerial Thermography with InfraTecRead onDownload ZIP-File (3428 kB)In the upcoming free of charge InfraTec online event you learn more about the benefits, types and challenges of aerial thermography and get more information on applications for thermography in airborne remote sensing.

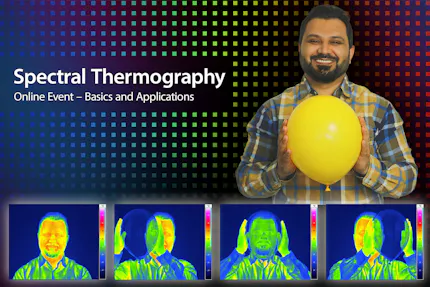

![Spectral Thermography – Basics and Application Spectral Thermography – Basics and Application]() 2024-09-10Online Event: “Spectral Thermography – Basics and Applications”Precision measurement using spectral IR thermographyRead onDownload ZIP-File (10174 kB)

2024-09-10Online Event: “Spectral Thermography – Basics and Applications”Precision measurement using spectral IR thermographyRead onDownload ZIP-File (10174 kB)Infrared thermography offers precise temperature measurement in various wavelength ranges such as short wave infrared (SWIR), mid wave infrared (MWIR) and long wave infrared (LWIR) of a wide range of materials.

![TarisIR® mini – When Size Matters TarisIR® mini – When Size Matters]() 2024-09-10TarisIR® mini – When Size Matters!The latest model in InfraTec's compact camera series impresses with excellentimage quality and smallest dimensions.Read onDownload ZIP-File (10882 kB)

2024-09-10TarisIR® mini – When Size Matters!The latest model in InfraTec's compact camera series impresses with excellentimage quality and smallest dimensions.Read onDownload ZIP-File (10882 kB)The TarisIR® mini is the latest radiometrically calibrated infrared camera in InfraTec's portfolio. It is designed for universal use and – with the associated IRBIS® software – enables entry-level access into stationary thermography at an excellent price-performance ratio.

![Detector Talks 2024 USA Detector Talks 2024 USA]() 2024-08-27Online Event: Detector Talks 2024The meaning of infrared filters and emitters for pyroelectric detectors in NDIR gas analysisRead onDownload ZIP-File (2943 kB)

2024-08-27Online Event: Detector Talks 2024The meaning of infrared filters and emitters for pyroelectric detectors in NDIR gas analysisRead onDownload ZIP-File (2943 kB)In the upcoming online event "Detector Talks 2024 – Infrared Filter and Emitter", InfraTec will present in detail which factors need to be considered when setting up a detector and how infrared filters and emitters influence your measurements.