System Cameras for Industrial and Laboratory Use

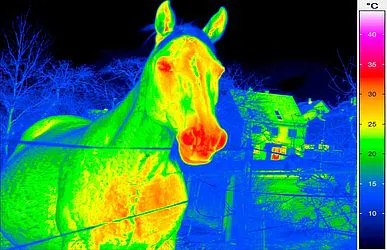

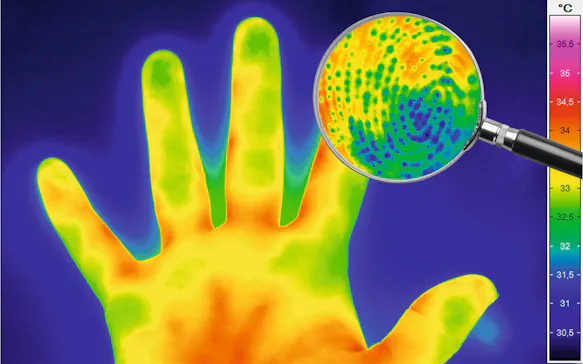

Thermography in HD Quality for New Dimensions

The system cameras from InfraTec have a wide range of interchangeable lenses and, in addition to compact housing dimensions, have a robust construction with a degree of protection up to IP67. All system camera series are available in numerous equipment and performance variants and enable customised thermography solutions.

Infrared Camera VarioCAM® High Definition of InfraTec

Geometrical resolution of detector formats with up to (1,024 × 768) IR pixels

Integrated into camera, genuine temperature measured values with up to (2,048 × 1,536) IR pixels

Precise detection of smallest temperature differences

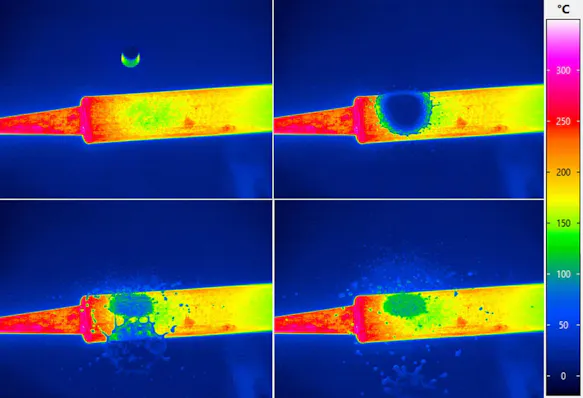

Analysis of high-speed dynamic temperature changes and processes

Easy and inexpensive installation in harsh process environments

Wide range of lenses – telephoto-, zoom- and microscope lenses

Models of System Camera Series

Infrared Cameras ImageIR® 8100 and ImageIR® 9100

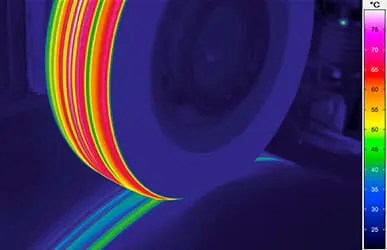

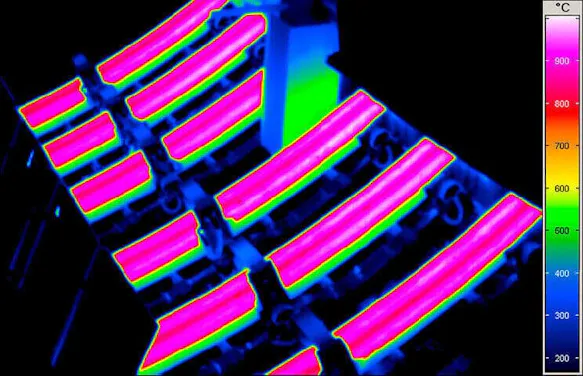

The SWIR infrared cameras ImageIR® 8100 and ImageIR® 9100 are radiometrically calibrated and available with (640 × 512) or (1,280 × 1,024) IR pixels in VGA or SXGA image format. They operate in the short-wave infrared range and allow, among other things, emissivity-optimised measurements of temperatures on metallic surfaces.

Infrared Camera Series VarioCAM® HD head and VarioCAM® HDx head

The infrared cameras of the VarioCAM® HD head and VarioCAM® HDx head series from InfraTec are based on uncooled microbolometer FPA detectors. With up to (1,024 × 768) IR pixels, the camera series delivers brilliant and detailed 16-bit thermal images with an outstanding frame rate of up to 240 Hz.

Innovations for Precise Performance

3,1 Megapixel thanks to MicroScan

The MicroScan technology works opto-mechanical and is designed for permanent operation. Due to FPA detectors of the latest generation with (1,024 × 768) IR pixels, this technology allows for a quadruplication of IR measurement pixels. They show real temperature values but not interpolated pixels. This opens up several new fields of application. Old measurement tasks become more efficient and therefore, valuable working time and costs are saved. Large-scale or far-flung measurement objects can now be recorded in one, fast, precise and complete recording due to the unique MicroScan technology.

EverSharp Function

The innovative EverSharp function allows all objects in the image scene to be brought sharply into focus, regardless of how far these are from the camera and which lens is used. Special algorithms ensure an automatic combination of several images with different focusing (multifocus images). In the resulting thermal image, a result from up to ten individual exposures, all object structures are thus sharply displayed so that the entire scene can be displayed and measured with the highest possible accuracy. The quality of the images depends entirely on the depth of focus of the lens used or the distance of the measuring objects from the camera. This means that the operation of the thermal imaging camera is even more convenient for the user.

Permanent Autofocus for Optimal Focusing

Constantly changing object scenes require manual or automatic refocusing. The integrated permanent autofocus function makes this task easier. In the case of a change of scene, the camera automatically applies the optimum focus setting quickly and precisely. The completely innovative, very powerful autofocus system is laser-based and works extremely reliably. Even under unfavourable environmental conditions, such as poor lighting conditions, darkness or low thermal contrasts on the measuring object, this function provides exactly focused thermal images.

Real-time Storage on SDHC Card

Recording dynamic scenes event-driven or timecontrolled at full speed and all temperature data – this is possible at any time with the camera's internal real-time storage on SDHC card. In this process, radiometric data is stored in IRB format (infrared image format), which can be processed and analysed efficiently with the IRBIS® 3 evaluation software afterwards. Consecutive numbering of the single frames within the sequence and storage of timestamps in the header ensure an exact time-based assignment of the thermal image data. The data can also be recorded as PNG or AVI files.

High-speed Image Storage

Operation of the VarioCAM® HD in so-called subframe mode (subwindowing) is provided for higher refresh rates. This mode enables the time or actioncontrolled recording of complex thermographic sequences with refresh rates of up to 240 Hz. For this purpose, one defined section of the detector is read out at a time and transferred by means of GigE-Vision.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.

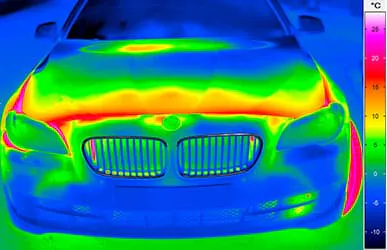

Industries and Applications for System Cameras

Research and Development

Whoever develops new products pays attention to every detail from the start. During the recording of even the smallest structures, you effectively avoid measurement errors due to geometry. The acquired data with a measurement accuracy of one percent meet the highest demands. You safely transfer the thermal images in your measuring environment via the GigE interface in the image format of up to (2,048 × 1,536) IR pixels at a frequency of up to 240 Hz. In addition, you adapt the VarioCAM® HD perfectly to your measuring task. The wide range of lenses ensures a high degree of flexibility when you are handling different sized measuring objects and variable operating distances.

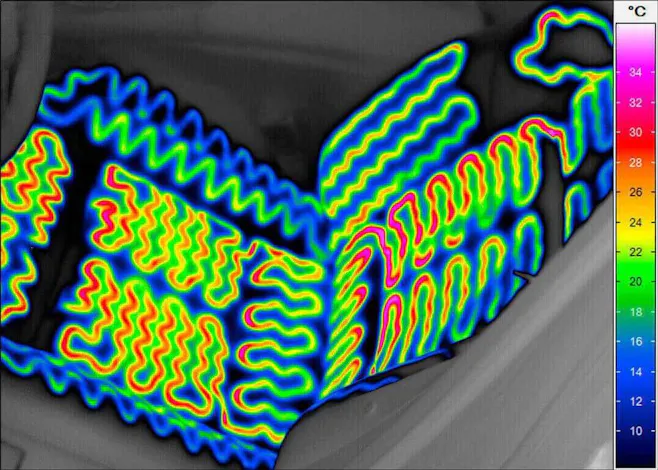

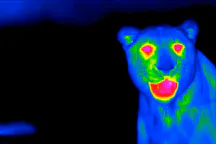

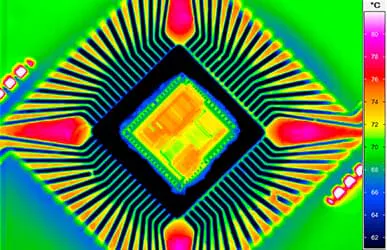

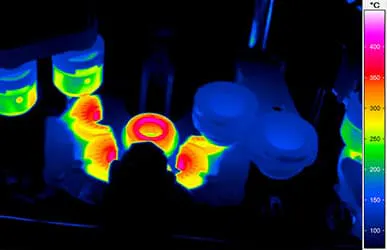

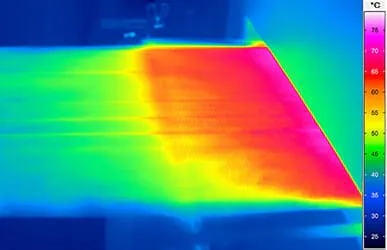

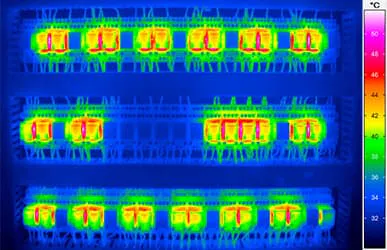

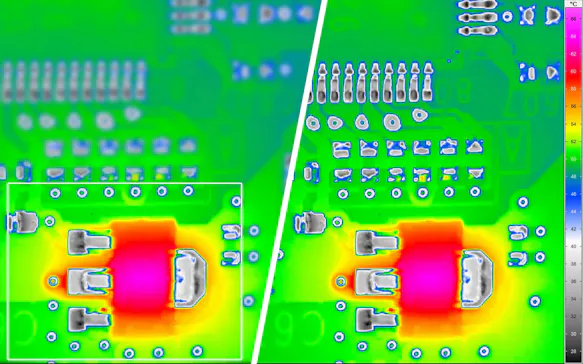

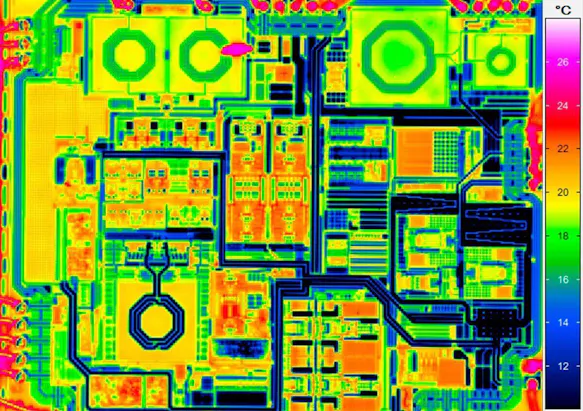

Microthermography

Complex electronic components are becoming increasingly powerful and smaller. For this reason, precision plays a crucial role during their development. The VarioCAM® HD allows you to analyse extremely small structures of up to 17 μm, which appear consistently sharp thanks to the EverSharp function, and to determine their temperatures exactly. The detector resolution of (1,024 × 768) IR pixels opens up adequate room for you to record your component reliably with sufficient, geometrical resolution. Thus, you obtain results with a high level of measurement accuracy.

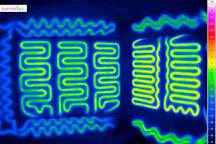

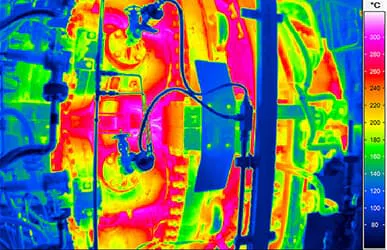

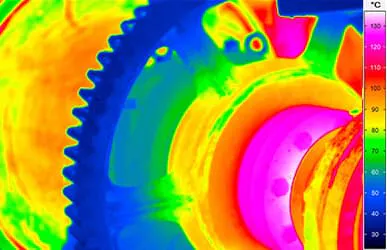

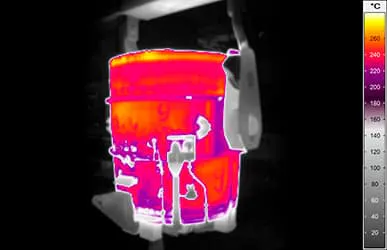

Process Optimisation

The continuous measurement in production processes places the highest demands on your devices. The compact light metal housing with IP67 of the VarioCAM® HD protects your camera even in harsh industrial environments. High-quality, protection class preserving LEMO® connectors ensure the transfer of the camera data. The GigE interface ensures fast and secure transfer up to 240 Hz in your system environment. The direct connection of the process interfaces to the special software IRBIS® 3 process allows your data to be integrated into the process environment.

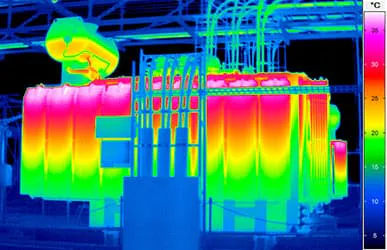

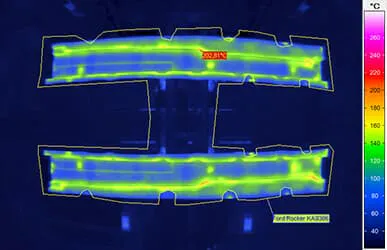

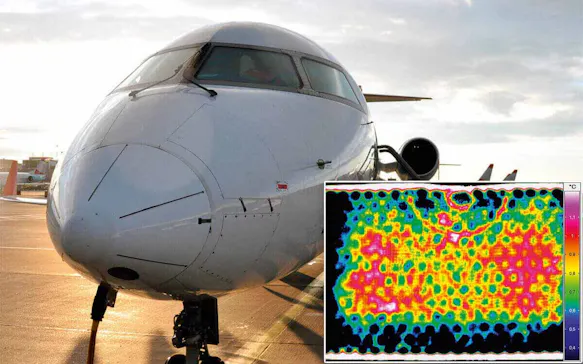

Non-destructive Testing

The combination of repeatable triggering and high thermal resolution predestines the VarioCAM® HD particularly for nondestructive testing. Firstly, you create thermal images via external signals, transmit temperature-dependent signals simultaneously and thus synchronously control your test process. Secondly, the thermal resolution of up to 0.02 K ensures noiseless reproduction of the smallest temperature differences. The IRBIS® 3 active thermography software, which is adapted perfectly to the thermal image camera, supports the evaluation and display of the corresponding results with its complex evaluation algorithms.

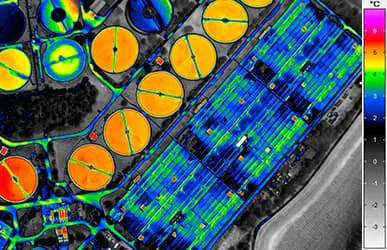

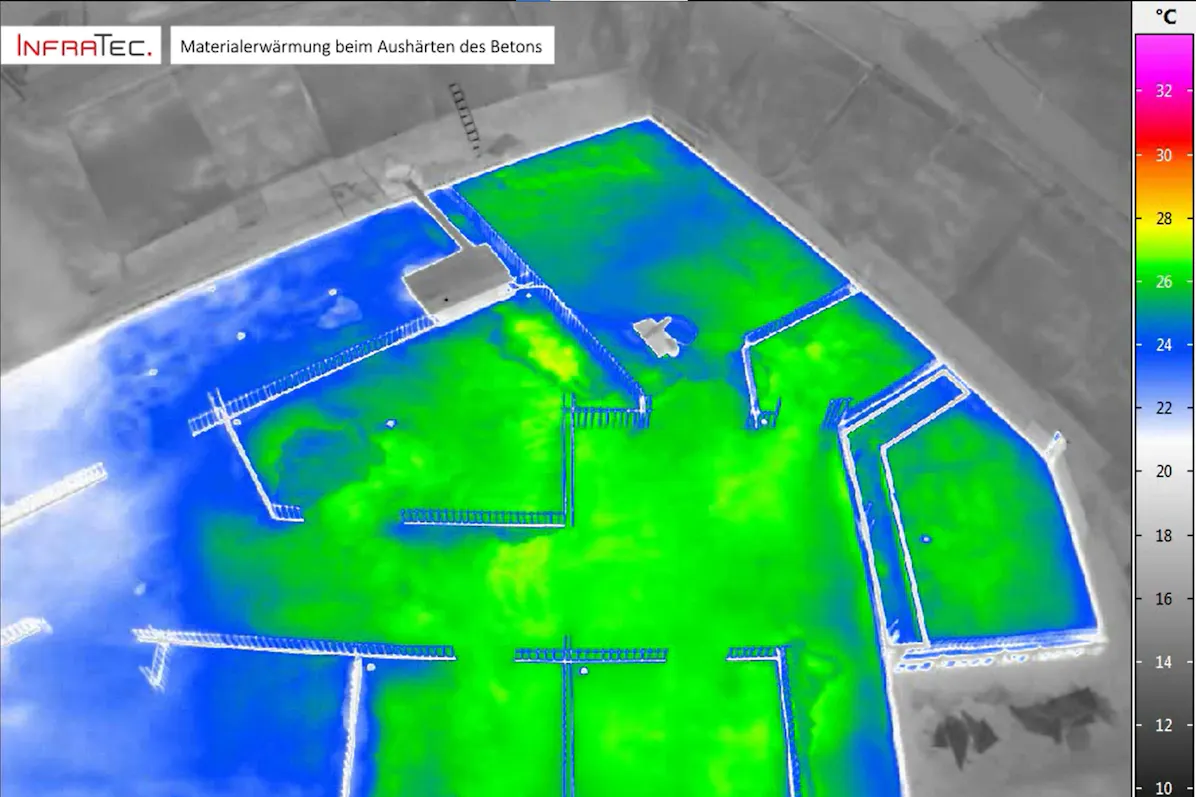

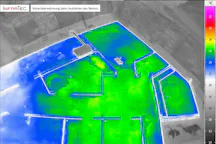

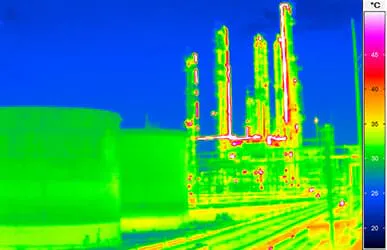

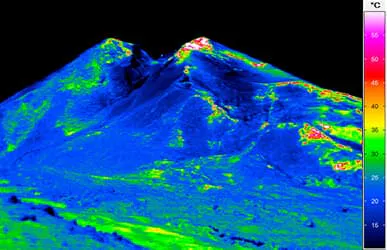

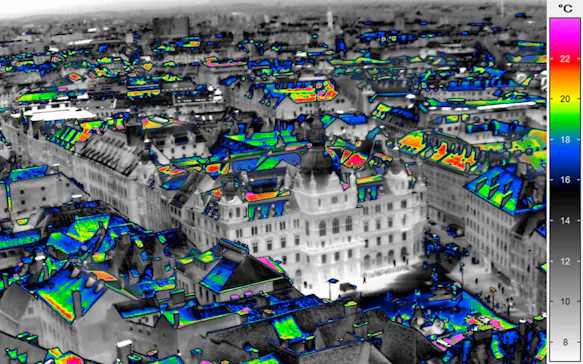

Airborne Thermography

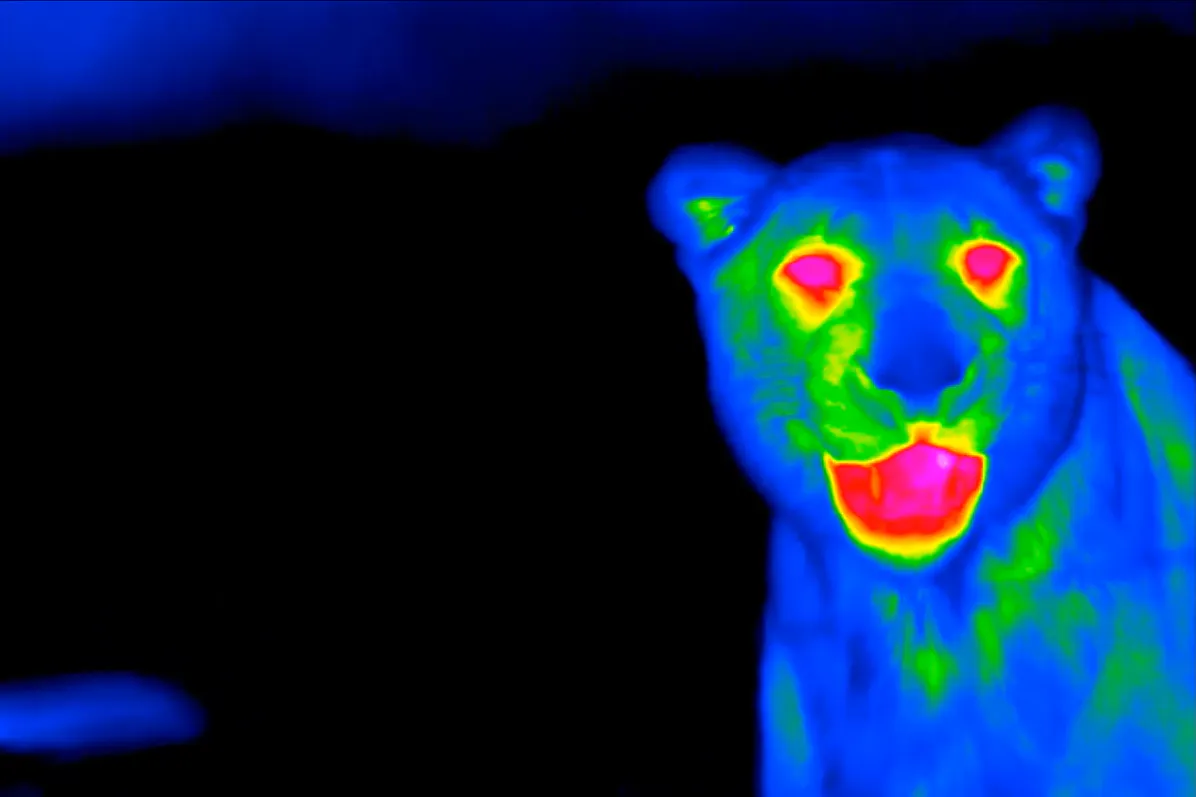

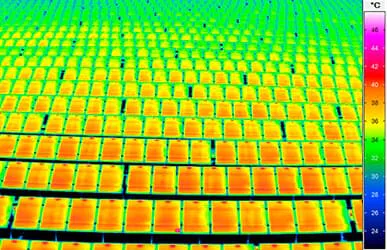

Do you want to inspect overhead electrical power lines, pipelines or industrial plants from the air? Or check large areas for energetic and material environmental pollution? Then the high-resolution VarioCAM® HD head is your choice. Integrated in gyro-stabilised platforms, so-called gimbals, the camera reliably records large-scale areas. You can determine and synchronously save the GPS coordinates from the camera location for each thermal image. In this way, you efficiently plan and effectively check from the air. The large range of interchangeable lenses also helps you to solve your measuring task.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Accessories and Product Flyer

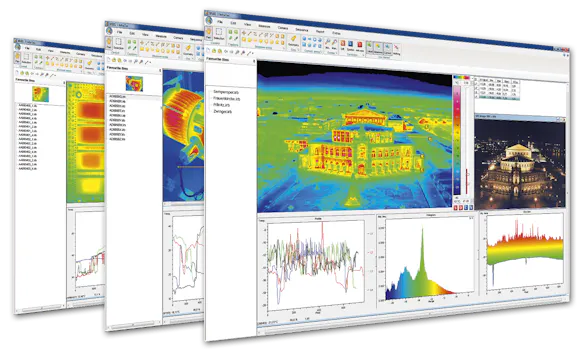

Fast and Detailed Analysis Using the Integrated IRBIS® 3 Software Package

The efficiency of an infrared camera significantly depends on its data analysis software. As a standard, the thermography software package IRBIS® 3 is included in each camera delivery. This software gives a fast, precise and detailed evaluation of obtained thermograms and sequences. With this, and the copy & paste function in all WINDOWS programmes a good basis is provided for comprehensive development work.

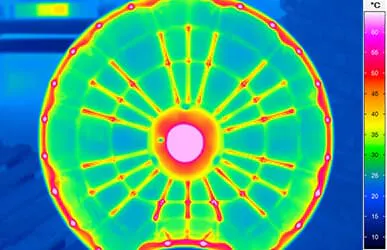

Lenses

The versatile range of precision interchangeable lenses of the VarioCAM® High Definition model series ensures maximum flexibility during their use. Possible measurement and inspection tasks include microthermography as well as telephoto applications for measuring objects at great distances. In this wide application spectrum, the lens design of the VarioCAM® HD camera series has proved to be an uncompromising, athermalised full lenses with the aperture f/1.0, highest transmission and quality as well as low distortion.

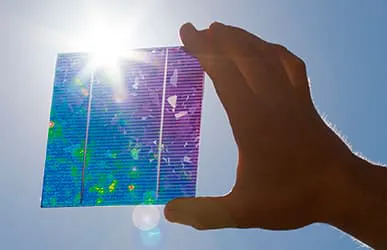

Thus, the camera ensures simple handling, very fast operational readiness and extremely accurate measurement results as well as consistent image sharpness even in the event of widely varying environmental temperatures. A special, highly resistant DLC coating protects the optically active surfaces of the lenses even under harsh conditions. Extensive measuring objects such as photovoltaic systems can also be thermographically measured reliably and efficiently, such as objects requiring safety distances, as in the case of highvoltage installations. When changing a lens, this is detected automatically by the camera and the stored calibration data is loaded.

InfraTec – Specialist for Infrared and Thermal Imaging Technology

InfraTec has been developing, producing and selling modern infrared technology for more than 30 years now. In addition to thermographic cameras, this includes turnkey thermographic automation solutions, infrared precision lenses, OEM components, software and a wide range of accessories. With more than 30 sales partners, the Dresden-based company is one of the world's leading suppliers of commercial thermography and thermal imaging systems. This enables customers to solve even the most demanding measurement and testing tasks in areas such as process optimization, quality assurance, research and development and material testing. In addition, InfraTec offers users a comprehensive range of services. This includes, for example, expert advice on the selection of technology, a calibration service and personnel training on the introduction of thermal imaging technology.