High-end Camera Series ImageIR® 9400

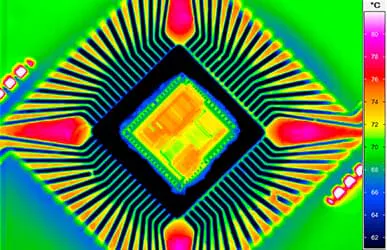

The infrared cameras of the high-end camera series ImageIR® 9400 score with their versatility and absolute best values for geometrical, thermal and temporal resolution. They have been designed for users with the highest demands in science and development, for object monitoring and micro-thermography for the analysis of extremely small structures. The modular concept of lens, detector and interface modules of the cameras ensures that users can configure their desired model individually and adapt it optimally to the respective task.

Innovations for Precise Performance

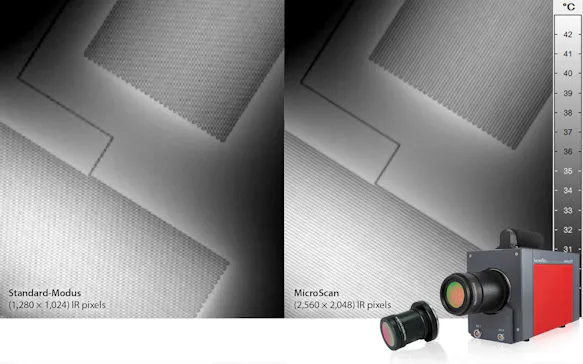

MicroScan – Quadruple the Image Format

Behind the function is a fast-rotating MicroScan wheel, which is integrated into the camera. It ensures that four different individual exposures are taken per wheel revolution, which are offset laterally by half a pixel each. These individual exposures are brought together in real time into a thermogram with quadruple image format. Each pixel in the image represents a genuine temperature measured value and not an interpolated image point. In this way, thermography achieves a new quality due to thermal images providing a spatial resolution up to 3.7 Megapixels.

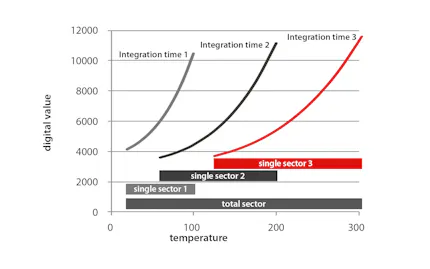

High-speed Mode – Increase Frame Rates and Thermal Resolution

If you want to analyze the thermal behavior of objects and processes from a wide variety of perspectives, you can use the high-speed mode for maximum flexibility. This function allows the camera to be used in two different operating modes. The standard mode suits best for depicting the smallest geometrical details. This allows users to record images with the native number of pixel of the camera detector. Switching to high-speed mode opens up the option of more than triple the frame rate, while the field of view (FOV) remains identical. This enables for most accurate time monitoring of fast processes. At the same time, the thermal resolution increases by a factor of 2 in high-speed mode, which additionally improves the analysis of temperature differences.

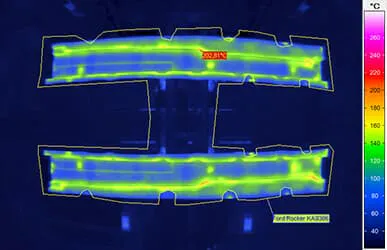

Efficient measurement of smallest structures on large-scale objects

Integrated into camera, genuine temperature measured values

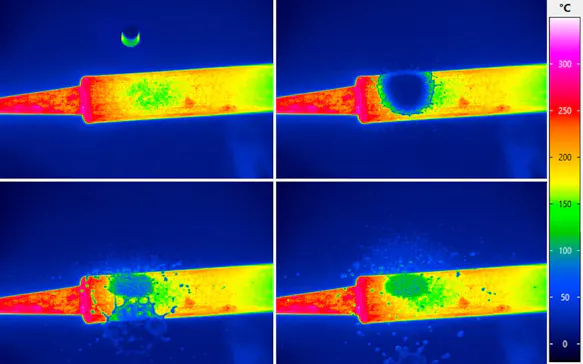

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

Precise detection of smallest temperature differences

High-speed, long-distance interference proof data transmission

Increases frame rates and thermal resolution at the same time using binning technology

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Integrated Trigger and Process Interfaces

The camera series ImageIR® is equipped with a snapshot detector as well as with an internal trigger interface, which guarantees a repeatable high-precision triggering. Two respective in- and outputs are used to operate the camera or to generate digital control signals for external devices. Two digital channels of the data stream can be recorded synchronously with those trigger inputs. Additional digital and analogue in- and outputs are available in connection with the process interface IRBIS® 3 process. Furthermore, extra information will be saved directly with the images.

Take Advantage of the Modular Concept for Your Flexibility

The closed, industrial-suited, high-strength aluminium alloy housing is very compact and protects the sensitive sensors and electronics even during roughest applications. It impresses with its low weight. The modular design allows for an application-specific configuration and later adaptation to varying demands. The interfaces are equipped with push-on connectors to uphold the degree of protection.

Detect Smallest Temperature Differences Using High Thermal Resolution of 20 mK

The thermal resolution of the ImageIR® infrared camera series allows you to measure smallest temperature differences of Better than 0.02 K (at 30 °C). Thermal images with a narrow temperature span display details absolutely sharp. You will find interesting signatures even there where other infrared camera systems cannot detect any temperature differences any longer.

You Need More Information about the ImageIR® Camera Series ImageIR®?

There is a ImageIR® matching perfectly your specific requirements. To find out which one it is, just check out all the models in detail.