ImageIR® 12300

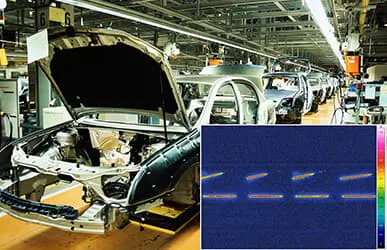

The new ImageIR® 12300 from InfraTec is the radiometrically calibrated infrared camera with the world's highest commercially available native resolution of 5.2 megapixel. The powerful top model of the ImageIR® series allows very fine structures on large area measurement objects to be resolved with unrivalled detail.

High-performance photon detector with maximum native resolution of (2,560 × 2,048) IR pixels

5 µm pixel pitch to avoid geometrically induced measurement errors

High-speed mode with frame rates up to 1,600 Hz

Multispectral measurement thanks to sequences with continuously changing spectral filters

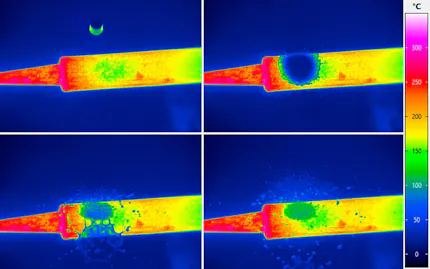

High resolution thermal images for monitoring large areas by (2,560 × 2,048) IR pixels

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

Precise detection of small temperature differences in high-speed mode

Smaller pixel sizes avoids geometrical measurement errors

Increase frame rates and thermal resolution at the same time using binning technology

Application specific spectral adaptation of the camera

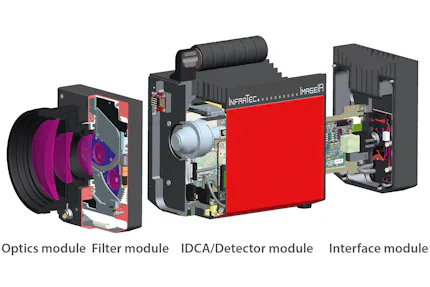

Integrated Intelligence for More Independence

The ImageIR® 12300 is equipped with high performance electronics with impressive processing bandwidth. IR image data obtained can be recorded internally, analysed using implemented algorithms and used to control the high-end infrared camera.

The ImageIR® 12300 is designed for standalone operations completely without a PC. Alternatively, data can be output in real-time via various interfaces to high resolution displays as well as for external processing or storage. The integrated web interface allows for operation and remote control of the ImageIR® 12300 by smartphone or tablet.

InfraTec ImageIR® High-end Infrared Camera Series

Master the Most Complex Measurement and Inspection Tasks Yourself

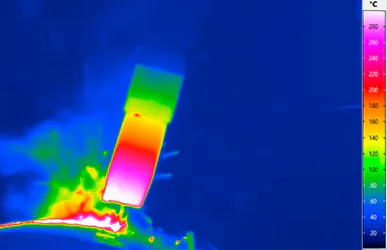

High object temperatures or specific material characteristics of the measurement objects can make analysis with thermographic systems considerably more challenging. For such cases, InfraTec offers equipment with an optional aperture wheel and filter wheel. It is motorised and can be operated through the camera controller.

For example, if extremely high temperatures on objects are measured, the apertures weaken the respective radiation accordingly. With calibrated measurement ranges, a previously determined aperture is automatically selected and used for image recording.

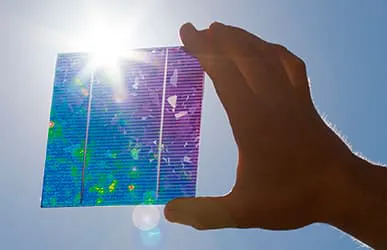

If specific emission or transmission characteristics of the measurement object make the task more difficult, users can equip the aperture wheel and filter wheel of ImageIR® with filters. As a result, the camera's range of use is expanded to cover the area of spectral thermography. In this way, transmission is prevented with thin foils and only their purely emitted radiation is recorded for temperature measurement. The wheel offers room for up to five spectral filters or apertures, so the thermography system can be adapted to target the measurement and inspection task on site.

Technical Specifications

| Spectral range | (3.4 … 4.9) μm |

| Pitch | 5 µm |

| Detector | xBn |

| Detector format (IR pixels) | (2,560 × 2,048) |

| Image recording principle | Snapshot |

| Readout mode | ITR / IWR |

| Aperture ratio | f/1.7 |

| Detector cooling | Stirling cooler |

| Temperature measuring range | (-10 … 1,700) °C, up to 3,000 °C* |

| Measurement accuracy | ± 1 °C or ± 1 % |

| Temperature resolution at 30 °C | Better than 0.045 K / 0.022 K in high-speed mode |

| Frame rate (full / half / quarter / sub frame) | Up to 140 Hz / High-speed mode: up to 1,600 Hz |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

*** Simulated values acc. to Johnson criteria for detection, recognition and identification with atmospheric extinction coefficient of 0.2/km and a probability of 50%.

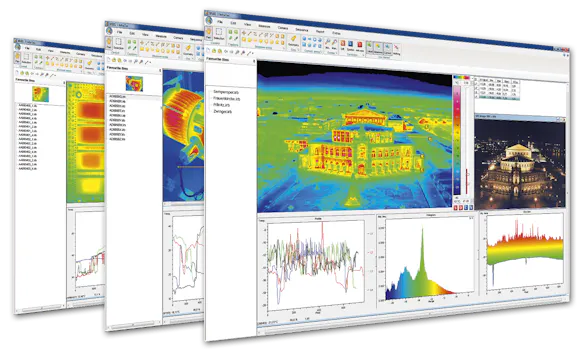

Comprehensive Thermography Evaluation Software for Efficient Operation

The software family IRBIS® 3, which was developed by InfraTec, is part of a complete system of the camera series ImageIR®. The comfortable and professional thermography software IRBIS® 3 professional offers a wide range of analysis- and editing tools to analyse sophisticated thermal investigations. The combination of ImageIR® together with the professional thermographic software meets all requirements that are set as standard for efficient high-performance tools for thermographic investigations.

Data Sheet Camera Series ImageIR® 12300

Get all the information you need at a glance in our data sheets.

Do You Have Questions? We Are Here For You!

Many requirements call for customized solutions. Our specialists provide personal support – whether you have technical questions, need assistance in selecting suitable system solutions, or want to ensure the optimal use of your infrared camera. Give us a call or send us an email. Together, we will find the right solution.

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.