What is an Thermal Camera?

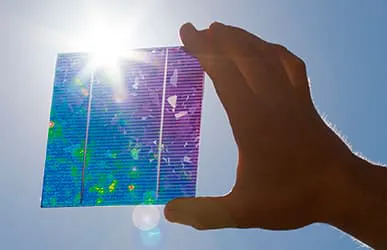

A thermal camera – also called IR camera, thermal imaging camera or infrared camera – is a measuring instrument used for non-contact measurements of the surface temperature of objects. Measuring temperature in this way enables you to visualise infrared radiation of objects or humans which are normally out of the normal visible spectrum. The thermal camera uses its integrated infrared detector to record the intensity and distribution of a certain spectrum of this electromagnetic radiation. The infrared camera is set up close to process it is controlling in order to immediately detect and rectify deviations from the parameters defined for this process. InfraTec provides such solutions for process monitoring and quality control as well as for research and development.

Choose Your Thermal Camera

InfraTec offers more than 30 thermal camera models. Choose a suitable IR camera form our product range including compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.

Powerful IR Camera Including Full Service Package

With a modular system consisting of different and industry-proven components, for individual thermal camera models or automated thermography solutions, InfraTec takes into account the occurring versatile requirements.

Does your daily business call for an extremely powerful thermal camera? If so, InfraTec is the right partner for you.

Wide range of cooled and uncool infrared cameras for handheld and stationary use

Application-specific software packages enable precise and efficient data evaluation

Turnkey thermographic automation solutions

Professional feasibility studies

Comprehensive range of services from 24-hour service hotline to extended warranties

German designed, developed and manufactured thermal imaging camera

Experienced sales and service partners enable local support levels

In-house service department, e.g. for on-site support, remote maintenance and recalibration of your IR camera

Model Variety of Thermal Cameras

We offer a comprehensive range of more than 30 infrared camera models. Our product range of IR cameras comprises entry-level devices, professional and universal cameras, high-end solutions as well as industrial thermal cameras and infrared imager. Together we will find the right package consisting of thermal camera, software, accessories and service for your specifique application.

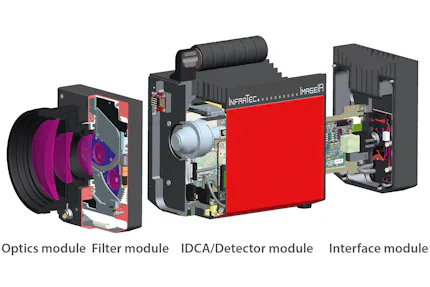

High-resolution ImageIR® Camera Series with Cooled Detectors

The high-end thermal cameras of the product series ImageIR® from InfraTec meet the highest demands in research and science, for non-destructive inspection as well as for process control. The modular concept enables excellent adaption to your specific measurement and inspection tasks. Cooled photon detectors of different types (InSb, MCT), spectral sensitivity ranges and formats are used. The numerous equipment options include powerful infrared full optics, filters and rotating aperture wheels, trigger and data transfer interfaces as well as motor focus units suitable for continuous operation.

Spatial resolution with detector formats with up to (1,920 × 1,536) infrared pixels

Integrated into camera, genuine temperature measured values

Precise detection of smallest temperature differences

Increase frame rates and thermal resolution at the same time using binning technology

Analysis of high-speed dynamic temperature changes and processes

High flexibility for upgrades and customization of configurations

Enables measurement tasks with high object temperatures and spectral thermography

Highly precise repeatable data recording; time- and event-controlled

System Cameras of VarioCAM® HD head Series

A wide range of interchangeable lenses and the compact housing dimensions of our system cameras as well as the robust construction with a degree of protection up to IP67 make these thermal cameras useful tools for many areas of application in industry and research. All system camera series are available in numerous equipment and performance variants and enable - depending on the application focus and requirements - individual thermography solutions.

High-end detectors with up to (1,024 × 768) infrared pixels

Available with unique opto-mechanical micro-scanner for up to (2,048 × 1,536) infrared pixels

Thermal resolution as low as 0.02 K

Frame rate up to 240 Hz

Cameras for fixed mount use in harsh process environments as well as for computer-assisted laboratory tasks

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

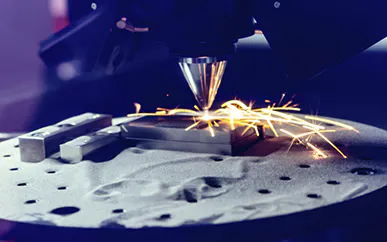

Possible Applications of a Thermal Cameras

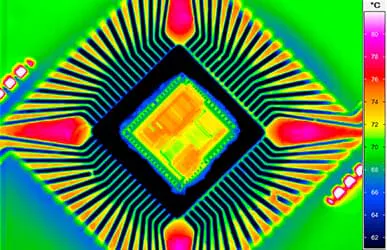

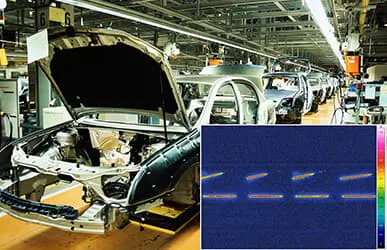

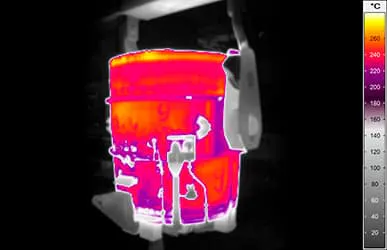

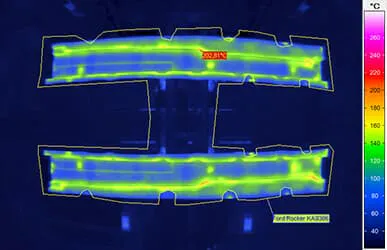

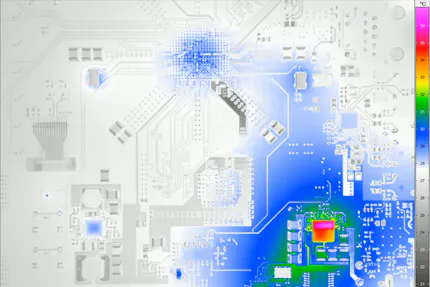

Especially when manufacturing thermally sensitive components, infrared thermography provides specific information for quality assurance purposes. In plastic- and automotive industries, even smallest deviations from the preset temperature can lead to a severe quality loss. With thermographic monitoring, the sources of error can be recognised, documented and fixed.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Frequently Asked Questions on the Subject Thermal Camera

A thermal camera - also called infrared camera - is used to measure temperatures of object surfaces. Therefore the principle of infrared thermography is used. Infrared thermography is a passive imaging method for contactless temperature measurement. It uses the fact that every object with a temperature above absolute zero (-273.15 °C) emits electromagnetic radiation. The focal plane array infrared detector of the thermal imaging cameras, which is equipped with individual elements arranged in a matrix, uses an optical system to capture the intensity distribution of the radiation emission from the measurement object over a large area. The camera converts the radiation intensities into measured temperature values for each individual pixel of the radiometric thermal image. This results not only in a few temperature readings from individual measurement points, as for example in the case of using thermocouples and pyrometers, but also in hundreds of thousands to millions of temperature readings that are completely distributed over the measurement object.

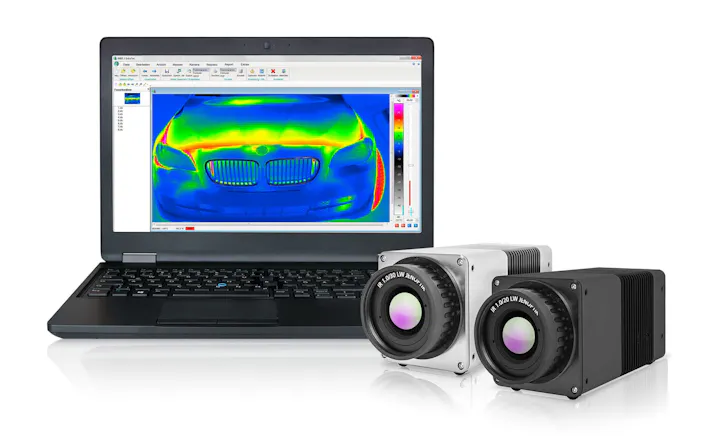

The visualization of images, also known as thermograms recorded by infrared cameras, can be performed in different ways. Best known are gray value or so-called false colour representations, in which each temperature value is assigned a gray level or a certain colour. Therefore, the user can get a very clear overview of the temperature distribution on the measurement object and immediately detect anomalies such as hotspots and discontinuities, which can indicate hidden faults for example.

The purpose of thermography is not only to collect image data, but to analyze and apply the obtained measurement results captured by an infrared camera. Using a thermography evaluation software the measurement data are processed. InfraTec offers a wide range of efficient and user-friendly programmes for various applications and requirements. The centre of attention is, hereby, the fully scalable software family IRBIS® 3.

Numerous companies from all over the world use infrared thermography as a measurement method in the development of new products, temperature-controlled process automation and quality control. Universities, technical colleges and institutes use ir cameras for applications in science and education. The spectrum of industries and application areas in which ir cameras from InfraTec are used is correspondingly broad. Learn more about the specific use of thermography in the user reports of our customers.