Thermography for Building Inspections

ARCHIMEDES Facility-Management GmbH is a full service provider for real estate and buildings. They offer comprehensive services ranging from planning, via facility management and building conversions up to complete refurbishment. Project Manager Dipl.-Ing. Olaf Hauck has increasingly regarded the usage of an infrared camera in his field of business as indispensable for fast and effectively detecting and analyzing poor conduction of builders´ work.

When ARCHIMEDES decided to purchase an infrared camera it went for the professional camera of the VarioCAM®-series by the German manufacturer JENOPTIK being exclusively represented by InfraTec in most of the countries. Olaf Hauck got especially convinced by this camera model because of its excellent thermal and geometrical resolution as well as its wide range of optionally available interchangeable lenses.

InfraTec Solution

ARCHIMEDES Facility-Management GmbH

Dipl.-Ing. Olaf Hauck

www.archimedes-fm.de

InfraTec Solution

VarioCAM®-series

The components of those special lenses and the camera itself are well tuned to each other guaranteeing an optimal result in the most different measurement situations. The ergonomic design of the infrared camera and the modern SONY battery concept being applied allow for a fatigue-free and convenient handling for long operation hours.

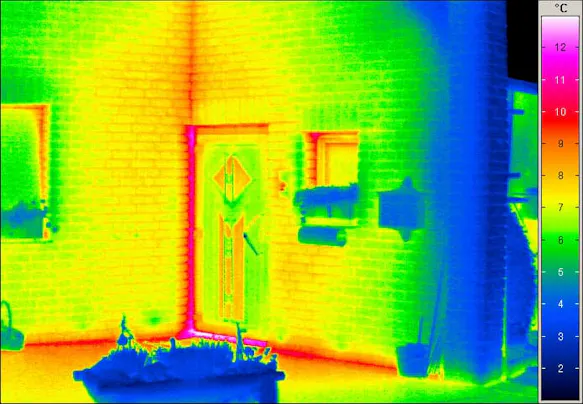

ARCHIMEDES uses its infrared camera predominantly for revisions and securing of quality standards during the construction phase of newly erected buildings and the refurbishment of older buildings. Thereby the detection of construction faults like thermal bridges, poor insulations or air leakages plays a major role. Also weak points at window or door framings can easily be located. Besides, for checking the outer shell of the buildings the camera is also used by Olaf Hauck and his team for a convenient exposure of covered leakages of pipes for floor heating and the like.

ARCHIMEDES also applies its infrared camera for thermography of electrical installations. Using the VarioCAM®-series dangerous points in electrical enclosures can quickly be found, e.g. corroded contacts or abnormally heated busbars.

Olaf Hauck praises the close consultation by InfraTec during the purchasing process but also thereafter. Additionally the two-days introductory training is highly appreciated by him as it allowed for a fast understanding of the infrared camera and the technological basics of infrared thermography. Thereby he and his colleagues got a fine grasp of the matter and could start working with the infrared camera.